While automated parking is accepted technology overseas, it has been slow to catch on in the US.

While automated parking is accepted technology overseas, it has been slow to catch on in the US.

As developers continue flocking to urban areas like Seattle and San Francisco to take advantage of the current market, they’re finding that success often hinges on one crucial question: Where are you going to park? The answer isn’t always simple; urban development often involves irregular footprints, high density locations often necessitate below grade parking facilities and costs can be prohibitive. Therefore, in order to find the right solution parking planners often have to stop thinking in terms of conventional parking levels and start thinking in terms of volume. Under these market conditions, automated parking solutions become part of the conversation.

Though automated parking systems are a tried, true and trusted commodity in Europe and Asia, the technology has been slower to catch on in the US. But as property values and construction costs continue to go up, the adoption of automated systems become more compelling. Watry Design, Inc. Principal and parking planning expert David LoCoco, recently named Chair of the Automated Committee for the National Parking Association, has explored a variety of different automated systems in order to tailor the best solutions for his clients.

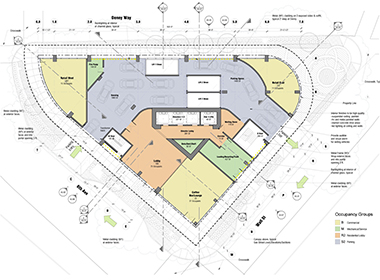

In the case of 600 Wall Street, a high rise residential development proposed in Seattle by Laconia Development, an automated solution seemed like a natural fit. In addition to being triangular in shape, the site is only 10,000 square feet and bordered by streetscape on three sides. Designing the tower itself on such a challenging site was no simple task, but when it came to parking, things got even more complicated.

The small, triangular site of 600 Wall Street in Seattle precludes a traditional parking solution.

The small, triangular site of 600 Wall Street in Seattle precludes a traditional parking solution.

“In order to provide the views they’ve envisioned, the tower’s structural core needs to be in the center of the building,” explains LoCoco. “This slices the available area to design the parking into 30 foot wide sections. Since a conventional parking setup requires 60 feet, conventional isn’t an option for this site.”

Automatic systems, however, provide more flexibility of space. Limiting human interaction can also provide added flexibility when designing on a small non-conventional site by minimizing the space traditionally required to accommodate people. The volume above an existing parking space can also be utilized more efficiently. Car elevators in lieu of speed ramps to deliver vehicles vertically are often key on these confined properties that have room to expand up but not out.

However like any parking solution, there is no one-size-fits-all when it comes to automated or semi-automated systems. Each project has its own unique goals, challenges and constraints and selecting the best system to meet those needs requires careful planning. In the case of 600 Wall Street, that planning entailed a 6,000 mile journey to China to get a firsthand look at several different systems in action.

LoCoco and Paul Menzies, CEO for Laconia Development, embarked on the trip with a representative from WRAP Parking, an intermediary who coordinates automated parking manufacturers with US distributors. Their first stop was a factory about 60 kilometers outside Shang-hi, where the trio met with the Executive Vice President of one of the larger producers of automated equipment. Together they discussed 600 Wall Street and how they might work together to customize a system that would accommodate the unique characteristics of the project.

Shuttle puzzle automated parking system in use in Taiwan.

Shuttle puzzle automated parking system in use in Taiwan.

“The site for 600 Wall Street is so irregular, there was a lot of value in getting everyone in the same room to discuss the potential challenges,” says Don Jagoda, WRAP’s president, who has worked with numerous automated systems and a variety of manufacturers. “I’m very pleased we were able to arrange it, because that collaboration will really benefit the project. Combining Dave’s expertise with the manufacturers who produce the systems and then seeing how those systems can be integrated will allow us to create parking within a workable pro forma.”

The team then boarded a plane to Taipei to see these systems in action. “Taiwan’s culture is so well adapted to automated parking,” LoCoco says. “It’s just part of their daily lives. And you don’t just see these garages in new construction. Existing buildings have been retrofitted to accommodate them, in some cases utilizing two or three different systems in the same location in order to make the most efficient use of space. It’s very exciting to see firsthand just how adaptable these systems can be.”

The impact of this trip is going to result in better parking design, for both 600 Wall Street and future automated parking projects. “Visiting the factory and working directly with the team in China is fundamental to establishing a strong relationship that will benefit everyone,” says LoCoco. “Leveraging their expertise in the early integration process is key to designing automated parking solutions for unique and challenging sites, which we are seeing more and more of.”

Mechanical lifts, or "stackers" nearly doubled Lumina's parking capacity vs. a traditional valet parking solution in the same space.

Mechanical lifts, or "stackers" nearly doubled Lumina's parking capacity vs. a traditional valet parking solution in the same space.

Interest in automated garages is certainly escalating. In May, West Hollywood opened a fully automated parking structure to support its City Hall. In Wichita, Kansas, LoCoco and the Watry Design team worked with Dallas developer John McWilliams to design an automated system that is now under construction for the Exchange Place apartment project. The luxurious Lumina high rise in San Francisco is nearing completion and will feature 24 hour valet and mechanically stacked vehicles on the lowers level for increased parking capacity.

More and more developers have approached LoCoco to explore automated possibilities for projects where providing sufficient parking has become a challenge. “Traditional buildings will start to implement these automated systems as more come online,” he says. “All of our hard work is paying off. We’re in the midst of some remarkable innovation that’s quickly becoming reality. I’m thrilled to be a part of it.”

Join our mailing list!

Thank you for signing up to receive parking insights and updates from Watry Design, Inc.!